Safety Systems

Operator safety is of the utmost importance to Accurpress. We offer many options to meet the safety requirements of your forming applications.

Laser Guarding Systems:

Accurpress press brakes can be equipped with either Lazersafe or Feissler Laser Guarding systems. This safety system allows the operator to work within close proximity (15mm) of the point of hazard while the tools close at high speeds. If an obstruction brakes the parallel beam across the tooling, Ram motion is immediately halted. This significantly increases the productivity of the press brake while constantly monitoring the point of hazard.

Light Curtain:

Light Curtain Guarding consists of a transmitter and receiver along with the controller, which is designed to meet the appropriate OSHA and ANSI standards when setting correctly for the job. In operation, the curtain extends a “curtain of light” in front of the hazardous area.

If a workers hand breaks the “curtain”, a signal is sent to the stop circuit on the machine. The curtain offers floating blanking and exact channel select to allow the operator versatility with various bending operations. In addition, the light curtain allows for muting in the slow pressing speed. External limit switches are adjusted for the appropriate muting location.

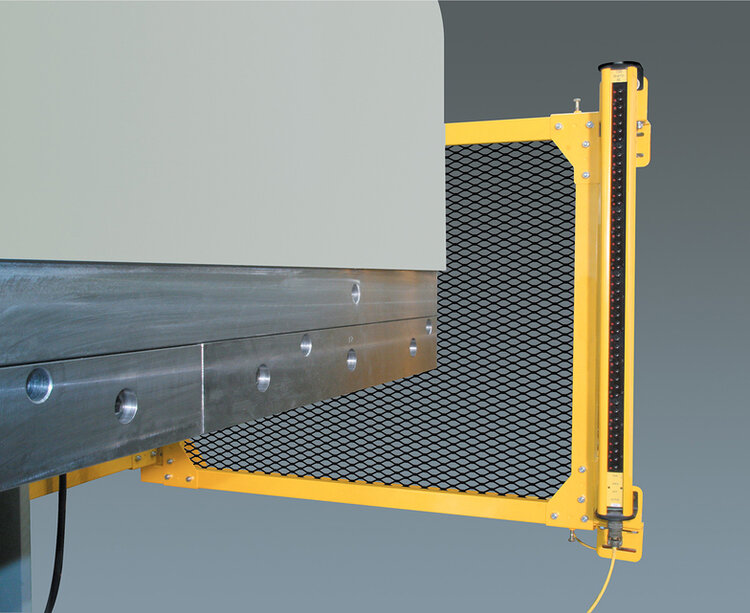

Rear Guarding:

Accurpress offers a rugged, modular aluminum gate that prevents operator access to unsafe work areas behind the machine unless the access door is utilized. When the access door is opened a safety interlock switch prevents the machine from turning on while the operator accesses the backgauge area. Rear Guarding is available for all press brake models and is a standard feature for machines equipped with either a 6-axis or Titan Backgauge.